Winemaking

The latest generation vat room

The ascension of oenological science

Winemaking at Lynch-Bages evolved in step with oenological knowledge.

Following a thorough study of the vineyard of Lynch-Bages and the new intra-plot distribution, the technical team began to draw up specifications to design a new winery taking on board viticultural developments.

The new winery project included the latest functional equipments such as destemmers, crushers, horizontal presses, stainless steel vats, instruments for measuring and regulating temperatures, and other highly sophisticated equipment.

The new winery has been designed with wine in mind and it is thought to be ergonomic and functional.

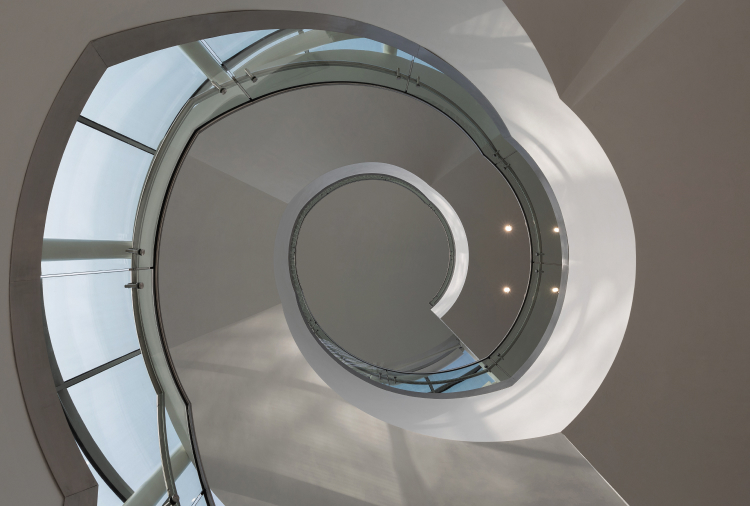

The building – designed by architect Chien Chung (Didi) Pei – is resolutely modern, and integrates seamlessly into its environment and leans on the sky, playing with natural light and transparency. As in the 19th century, the architectural structure is designed to overcome modern-day challenges: ergonomics, safety and environmental concerns.

Following a thorough study of the vineyard of Lynch-Bages and the new intra-plot distribution, the technical team began to draw up specifications to design a new winery taking on board viticultural developments.

The new winery project included the latest functional equipments such as destemmers, crushers, horizontal presses, stainless steel vats, instruments for measuring and regulating temperatures, and other highly sophisticated equipment.

The new winery has been designed with wine in mind and it is thought to be ergonomic and functional.

The building – designed by architect Chien Chung (Didi) Pei – is resolutely modern, and integrates seamlessly into its environment and leans on the sky, playing with natural light and transparency. As in the 19th century, the architectural structure is designed to overcome modern-day challenges: ergonomics, safety and environmental concerns.

Ergonomy

The harvest reception hall,

spacious and versatile

spacious and versatile

The grapes are picked exclusively by hand. A first sorting is done in the vineyard on mobile tables. As soon as they arrive at the reception area, the grapes are destemmed, and sorted manually a third time on vibrating tables.

Three reception lines allow us to harvest up to 12 hectares per day.

The berries are moved from the ground level by gravity flow using seven hectolitre mini-vats, and are distributed into each tank without pumping.

Sheltered and secure, the harvest reception area can also accommodate the bottling line.

The large translucent Kalwall door, with its sliding mechanism, optimises the space while allowing natural light flow.

The berries are moved from the ground level by gravity flow using seven hectolitre mini-vats, and are distributed into each tank without pumping.

Sheltered and secure, the harvest reception area can also accommodate the bottling line.

The large translucent Kalwall door, with its sliding mechanism, optimises the space while allowing natural light flow.

Innovation

The latest generation vat room,

a tool adapted to intra-plot selection

a tool adapted to intra-plot selection

We have doubled the number of vats from 40 to 80.

Now that we have 80 smaller tanks, we can precisely adapt our vinification process to the intra-plot mapping of the vineyard.

Traceability – plot, grape variety – is total at all stages of the process.

The tapered, new generation isothermal vats have a “double skin” and an integrated, individual temperature control system. Each tank is equipped with a pump with helicoidal impeller which is ideal for gently transferring liquids with solid particles (seeds, skins, etc.).

These pumps are specially adapted to pumping-over operations as they facilitate tannin extraction, while providing great ease of use.

Now that we have 80 smaller tanks, we can precisely adapt our vinification process to the intra-plot mapping of the vineyard.

Traceability – plot, grape variety – is total at all stages of the process.

The tapered, new generation isothermal vats have a “double skin” and an integrated, individual temperature control system. Each tank is equipped with a pump with helicoidal impeller which is ideal for gently transferring liquids with solid particles (seeds, skins, etc.).

These pumps are specially adapted to pumping-over operations as they facilitate tannin extraction, while providing great ease of use.

Gravity

Six elevator-mounted tanks

in the center of the building

in the center of the building

Six 100 hectoliter elevator-mounted tanks complete the gravity system.

During winemaking operations, up to bottling, they allow for smooth and easy “delestage” from tank to tank and ensure the connection with the underground barrel cellar.

The operations are controlled by means of a synoptic screen. These equipments bring flexibility and precision to the whole winemaking process, maximizing the quality potential of our wines.

During winemaking operations, up to bottling, they allow for smooth and easy “delestage” from tank to tank and ensure the connection with the underground barrel cellar.

The operations are controlled by means of a synoptic screen. These equipments bring flexibility and precision to the whole winemaking process, maximizing the quality potential of our wines.

Functionality

The underground barrel cellar,

two vintages side by side

two vintages side by side

The barrel cellar is located below ground level. Two harvests can be aged side by side in order to optimize wine maturation. The barrels are stacked up to two levels which facilitates barrel work tasks, and enables safer and more efficient operations without space constraints.

As in the vat room, the work is done by gravity.

Barrels are filled by pipelines and the wine is brought up thanks to the elevator-mounted tanks. Racking is performed from one barrel to another, and no pumping is necessary during the entire maturation period.

As in the vat room, the work is done by gravity.

Barrels are filled by pipelines and the wine is brought up thanks to the elevator-mounted tanks. Racking is performed from one barrel to another, and no pumping is necessary during the entire maturation period.

“Architecture is the masterly, correct, and magnificent play of masses brought together in light.”

Le Corbusier

The environmental dimension

Towards energy self-sufficiency

The vat room has an industrial-inspired sawtooth roof, comprising a succession of gabled roofs with a large north-facing window. It leans on the sky, allowing our teams to work in an environment flooded with natural light.

The roof was inspired by the design principles of England’s textile workshops, before electric lighting became widespread.

The vat room’s effective anti-UV glass and the protective screen of metal mesh on the south side keep its interior naturally cool without air-conditioning, even in the summer. The roof can accomodate solar panels in order to have an energy- self-sufficient building in the future.

The barrel cellar is located below ground level, to make effective use of temperature inertia. The hygrometry and temperature control systems are located in the ceiling and hidden by a stainless-steel mesh vault, a technical and architectural feat.

As in the vat room, light plays an important role. LED lighting was given careful thought, and skylights located in the elevator-tanks area provide natural light flow.

The vat room’s effective anti-UV glass and the protective screen of metal mesh on the south side keep its interior naturally cool without air-conditioning, even in the summer. The roof can accomodate solar panels in order to have an energy- self-sufficient building in the future.

The barrel cellar is located below ground level, to make effective use of temperature inertia. The hygrometry and temperature control systems are located in the ceiling and hidden by a stainless-steel mesh vault, a technical and architectural feat.

As in the vat room, light plays an important role. LED lighting was given careful thought, and skylights located in the elevator-tanks area provide natural light flow.

Visit

Awaken your senses…

Discover our facilities, book a guided tour or a tasting session, by appointment.

Book your tour